Integrity Management Program

The Pipeline Safety Improvement Act of 2002 mandated significant changes and introduced new requirements altering the ways that the oil and gas industry ensures the safety and integrity of its pipelines. The new law required each pipeline operator to prepare and implement an Integrity Management (IM) Program, which among other things, includes requirements to identify high consequence areas (HCA), conduct risk analyses of these areas, perform integrity assessments according to a prescribed schedule and using certain approved methods, and continually evaluate the program and assets through performance measures and continual assessment. Even a decade after operators laid foundations and frameworks to their Integrity Management Programs, many still struggle to meet the intent of the rule and effectively manage the program. GCR Integrity’s founder has been involved in designing and implementing IMP manuals, processes, and procedures since the inception of the rule, working with both large and small gas and liquid operators, as well as DOT-jurisdictional assets at marketing terminals and refineries.

Process & Procedure Development

Clear, concise, and effective procedures are essential for the successful implementation of any program or work process. Procedures require periodic updates and reviews, to ensure that they meet the latest rules and regulations and are kept up-to-date with current operations. Many employees fail to follow procedures because they are poorly written, confusing, or outdated.

We work closely with operators by listening to their needs, understanding their operations, resources, and corporate structure, then find ways to improve upon existing processes or address procedure gaps. Our focus and expertise include—but are not limited to—creating understandable and effective procedures that are easy to implement, addressing documentation and record keeping gaps, developing forms to document compliance activities, and tracking performance.

Pipeline Data Management and QA/QC

Every operator is familiar with challenges related to managing vast amount of pipeline data and records. Whether they are PHMSA (or State inspectors), internal auditors, accounting and business development groups, operations, management–everyone needs quick access to current, reliable, and accurate data. Construction work, maintenance activities, rehabilitation projects, or acquisitions of pipeline assets from other operators–all require a lot of time and resources to ensure that essential data is captured, transferred, and retained properly. Large amounts of pipeline data and vital records still remain in paper format in boxes, storage archives, and on the bookshelves of field offices. It is necessary for that data to be reviewed and filed appropriately so that it is easily accessible to all the personnel and organizational groups that rely on that data in daily operations.

As-built drawings, mill test reports, pressure test records, repair data–those are just a few examples of data that is often lost or misplaced, but are essential for compliance and day-to-day operational needs. We can help your company to develop a good recordkeeping structure as well as gather, scan, and file all critical records to make them accessible for easy retrieval through shared drives or GIS applications. We can also review and verify calculations that depend on this data, such as Maximum Operating Pressure (MOP) or Maximum Allowable Operating Pressure (MAOP) determinations.

Jurisdictional Applicability Assessments

Pipeline rules and regulations are not always straightforward or easy to interpret. Even industry experts and long-time operators struggle with “grey areas” of the rules, which are often confusing or unclear. Correct delineation of jurisdictional boundaries is important in order to stay compliant and manage each asset accordingly. EPA, US Coast Guard, OSHA, PHMSA – each have a set of regulations and inspection requirements for assets that fall under their jurisdiction. We are experienced in conducting field walkthroughs to help you determine the correct jurisdictional boundaries for pipelines, tanks, pump stations, and associated facilities.

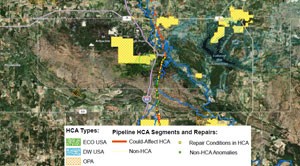

Mapping and GIS Implementation Support

We support our clients in the effective implementation and application of GIS software products. No pipeline Integrity Management Program is complete without GIS, an essential element for mapping and data management. Most operators are familiar with the PODS (Pipeline Open Data Standard) model, which provides the database architecture to store critical information and analysis data about pipeline systems. PODS enables operators to manage this data geospatially in a linear-referenced database which can then be visualized in any GIS platform. Typical information stored in a PODS database includes features like centerline location, pipeline materials and coatings, MAOP, valves and pipeline components, cathodic protection facilities and inspection results, hydrotesting, repairs, foreign line crossings, geographic boundaries, etc. Many new software tools for mapping and alignment sheet generation use GIS and PODS and are faster and more efficient than creating and updating these drawings in AutoCAD. Successful PODS implementation makes data retrieving and reporting an easy task, which we can assist you in navigating.

Facility Response Plans – OPA 90

The Clean Water Act of 1972 states that certain facilities that store and use oil are required to prepare and submit plans to respond to a worst case discharge of oil and to a substantial threat of such a discharge. The Clean Water Act was amended by the Oil Pollution Act in 1990 (known as “OPA 90”), primarily in response to Exxon Valdez oil spill in Prince William Sound, Alaska. OPA 90 was designed to expand oil spill prevention measures and to establish new requirements for oil transportation, cleanups, and response capabilities. Facilities that store and transport oil and could reasonably be expected to cause “substantial harm” to the environment from a discharge to navigable waters of the U.S. or the adjoining shoreline, must prepare a Facility Response Plan (FRP). Some facilities must meet the requirements of two or more federal agencies, because they engage in activities that fall under the jurisdiction of those agencies. These agencies include the U.S. Coast Guard, the Department of Transportation’s (DOT) Office of Pipeline Safety, and Environmental Protection Agency (EPA). A facility with both transportation-related and non-transportation-related activities is considered a complex and must comply with all the regulatory requirements of all applicable agencies. For example, a complex may have a marine transportation-related transfer area regulated by USCG or a pipeline regulated by DOT and a non-transportation-related oil storage area regulated by EPA. Our consultants had helped owners and operators of facilities that store or use oil to better understand the Federal Oil Pollution Prevention regulations and determine what specific requirements apply to their refinery storage tanks, tank terminals, or pipelines. We reviewed, revised, and submitted plans to agencies and obtained their approval.

Public Awareness Programs and Mailings

Federal pipeline safety regulations require pipeline operators to implement public awareness programs and provide pipeline safety information to four stakeholder audiences: 1) affected public, 2) emergency officials, 3) local public officials, and 4) excavators. We can assist by helping you to develop and implement public awareness program that follows the guidelines provided by the API Recommended Practice 1162, “Public Awareness Programs for Pipeline Operators”. We can also conduct program effectiveness evaluation to address various elements of your program, including a review of intended audiences, the quality and appropriateness of information that is being communicated, the frequencies and methodologies for communicating the information, and the overall effectiveness through surveys and feedback. We work closely with printing and mass-mail companies to develop the graphic content of your brochures and turn-key mailing process, facilitate collecting response cards, and analyze survey results.

Regulatory Compliance and Audit Support

Over 2.5 million miles of pipelines in the U.S. are subject to the requirements of Federal regulations in 49 CFR 192 (gas) or 49 CFR 195 (liquids). 85% percent of these pipelines are under State authority. The Department of Transportation’s (DOT) Pipeline and Hazardous Materials Safety Administration (PHMSA) regulates all inter-state lines and authorizes States to oversee and enforce compliance with Federal pipeline safety regulations on intra-state lines. Many operators are familiar with “standard inspections”, “OQ inspections”, or “IM inspections” that happen every 2-5 years, based on numerous factors. In 2008, PHMSA began implementing an “Integrated Inspection” (II) process. By using data and information about a specific operator and pipeline system, an inspector interviews the operator (via email form or actual on-site meeting) and then builds a custom a list of regulatory requirements to be evaluated during an inspection. This data-driven process allows PHMSA to focus inspection resources on the regulatory provisions addressing the greatest identified “risks”. For many operators, regulatory inspections are not only a time-consuming and resource-demanding process, but also a stressful event. No matter how confident you are in your programs or records, there is always some anxiety associated with the word “audit”. Our consultants are here to help you with audit preparation, on-site support during the inspection itself, as well as post-audit work. We have experience and been through numerous PHMSA and State inspections and are well prepared to assist you and guide you through this process.

412-362-9811

412-362-9811